Strategically located in close proximity to a wide variety of abattoir facilities, LAMPIRE is able to fill your large volume serum and plasma needs quickly and efficiently. Our experienced technicians have extensive training on the collection and processing of abattoir whole blood to ensure high-quality material. Abattoir blood is collected from normal healthy animals that have passed an ante-mortem inspection by the USDA (where applicable). See our product listing below or contact Customer Service for more information.

...Read moreStrategically located in close proximity to a wide variety of abattoir facilities, LAMPIRE is able to fill your large volume serum and plasma needs quickly and efficiently. Our experienced technicians have extensive training on the collection and processing of abattoir whole blood to ensure high-quality material. Abattoir blood is collected from normal healthy animals that have passed an ante-mortem inspection by the USDA (where applicable). See our product listing below or contact Customer Service for more information.

- Numerous anticoagulant options for plasma collection

- Multiple processing options for serum products

- Bulk quantities/large scale manufacturing available

- Export ready: LAMPIRE’s facilities have APHIS registrations to export most products into the EU

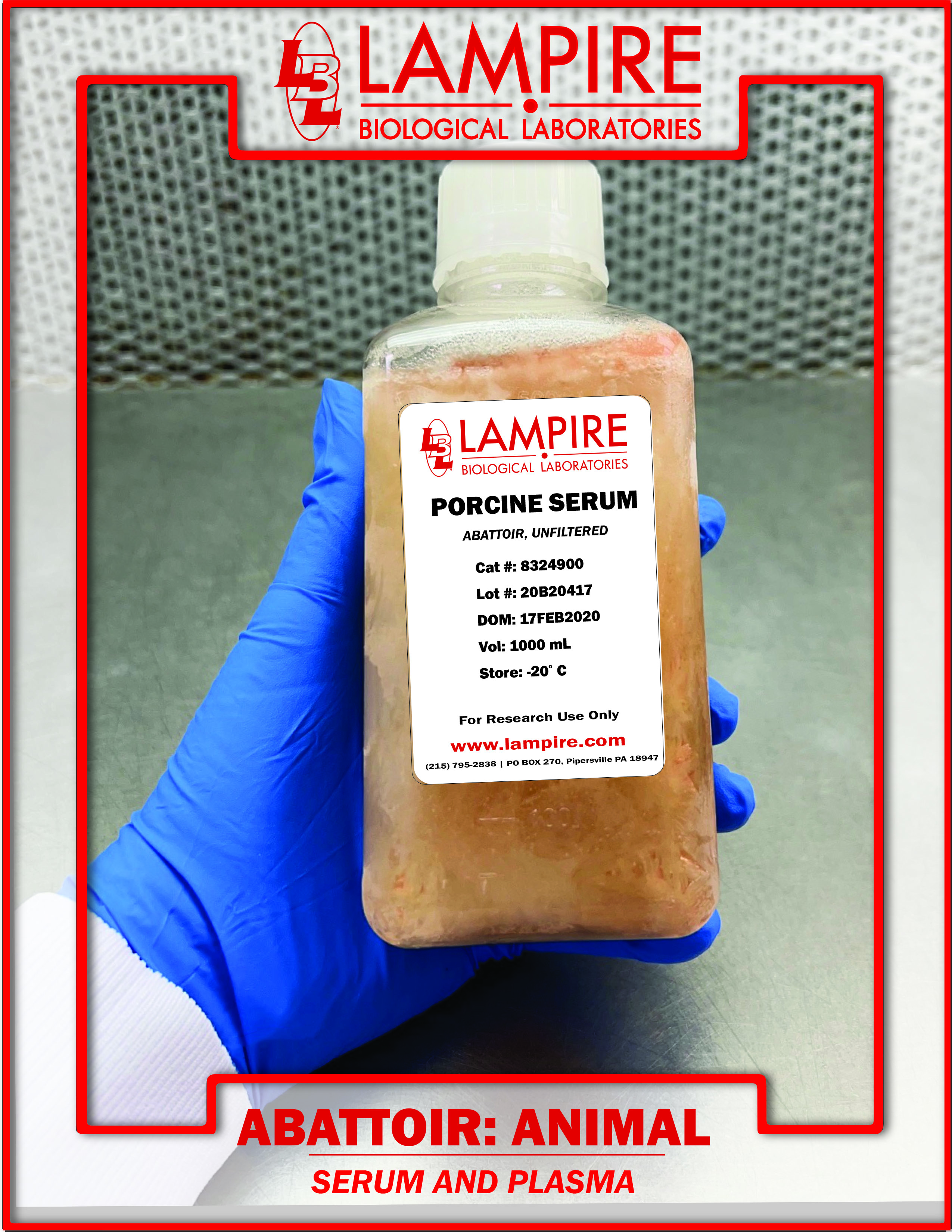

Abattoir Serum:

Serum is manufactured from abattoir animal whole blood collected into a bottle without anticoagulant. This material is allowed to clot. The blood is then centrifuged to remove the clot, red blood cells and buffy coat, then frozen. Product is tested for pH and total protein (via refractometer). Available as “unfiltered” (as described above), or “filtered”. The filtered product is run through a 0.2µm membrane and undergoes a 48 hour microbial content screening process prior to shipment.

Abattoir Serum Processing Options:

- Delipidation: Silica is added to the serum, which binds to the lipids, both of which are then removed via centrifugation. Suggested in certain species such as mouse or porcine, where serum is innately turbid.

- Heat Inactivation: Serum is heated to a temperature of 56°C for 30 mins, then immediately placed in an ice bath to prevent overheating. The serum is then centrifuged to remove precipitates. The intent is to inactivate complement and/or destroy mycoplasma.

- Charcoal Stripping: Activated charcoal is added to the serum, which binds to non-polar molecules such as lipids and hormones. The charcoal is then removed via centrifugation and run through a 0.2µm filter to clarify. Suggested for research where lipids or hormones can interfere with the results of an assay.

Abattoir Plasma:

Plasma is manufactured from abattoir animal whole blood collected into a bottle containing a specified anticoagulant. The blood is then centrifuged to remove the red blood cells and buffy coat, then frozen on the same day as collection. Product is tested for pH and total protein (via refractometer). Available as “unfiltered” (as described above), or “filtered”. The filtered product is run through a 0.2µm membrane and undergoes a 48-hour microbial content screening process prior to shipment. It is recommended that this product be aliquoted in single use volumes, as multiple freeze-thaw cycles could impact the product’s performance.

Anticoagulants:

- Acid Citrate Dextrose (ACD/ACD-A)

- Alsevers

- Citrate Phosphate Dextrose (CPD)

- Citrate Phosphate Dextrose Adenine-1 (CPDA-1)

- Na-Citrate

- K2EDTA

- K3EDTA

- Na2EDTA

- Lithium Heparin

- Sodium Heparin

- Potassium Oxalate

- Potassium Oxalate + Sodium Fluoride

- Sodium Fluoride

- Other custom anticoagulants available, please inquire

Applications:

- Medical Device/Equipment Testing

- Assay & Diagnostics Research

- Hematology & Coagulation Controls

- ELISA, Immuno-precipitation & Western Blot

Species Available:

- Bovine

- Porcine

- Ovine

- Avian

- Other Species May Be Available, Please Inquire

Shipping Conditions:

Plasma and serum products are shipped frozen on dry ice, unless otherwise specified

Read less